During a recent April visit to Vermont, I (Ty Newell) had the opportunity to attend a free demonstration of a product called AeroBarrier. AeroBarrier is a novel whole house sealing process for both new construction and retrofits, developed from Mark Modera’s related duct sealing technology. Nate Gusakov of Zone 6 Energy, an AeroBarrier installer from New Haven, Vermont conducted the demonstration (and patiently answered my hundreds of questions). Silver Maple Construction (also from New Haven VT; Silver Maple co-owner Sean Flynn is also an owner of Zone 6 Energy) is building the beautiful 3500 sqft home (real stone masonry, built-in furnishings). Sean said they have used AeroBarrier on a couple dozen homes to date.

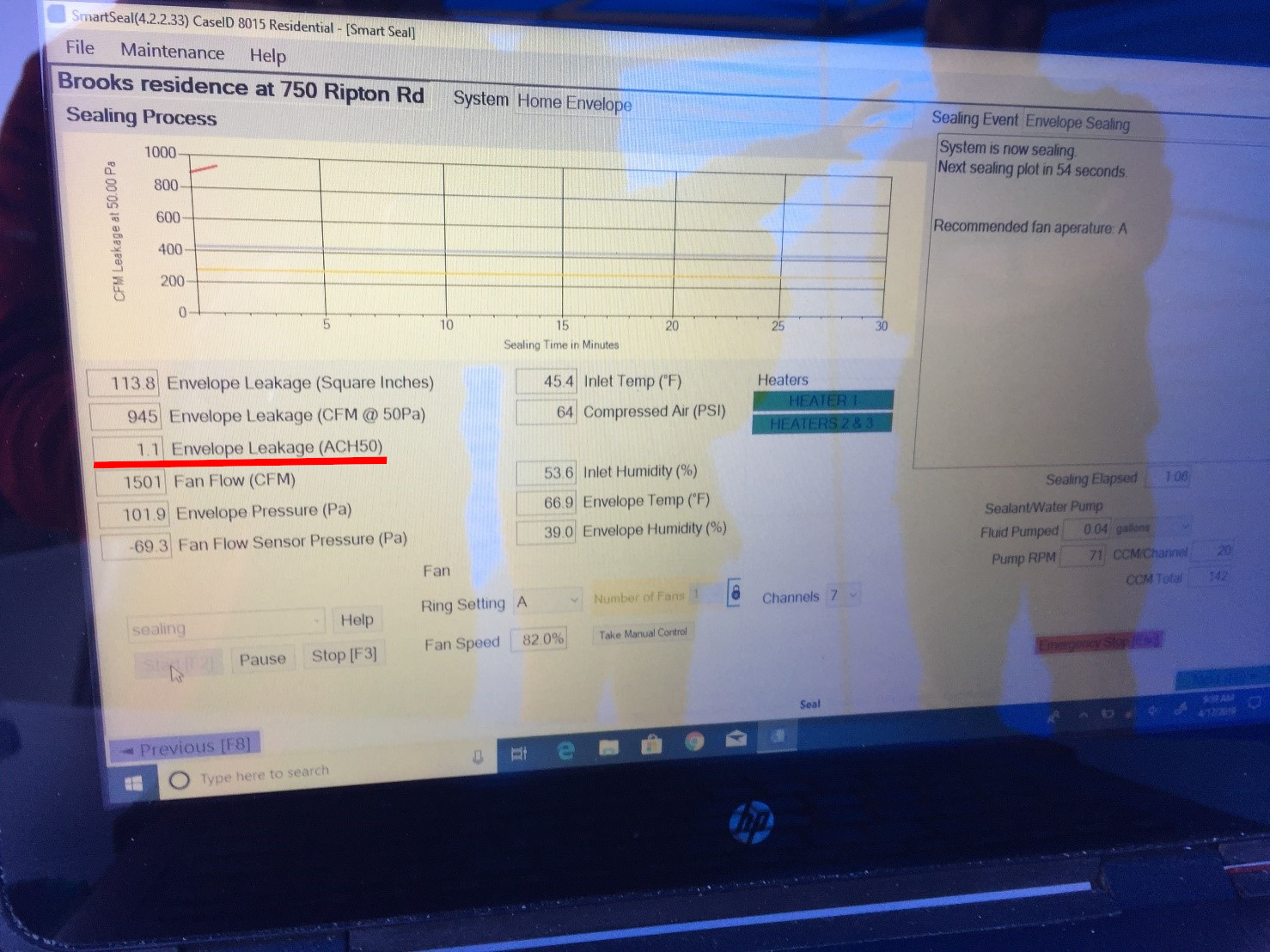

AeroBarrier consists of a thin latex paint smelling liquid that is atomized with 60psig compressed air in an array of spray nozzles distributed throughout a house. A blower door maintains 100Pa (0.4”H2O) positive pressure in the house, driving the fog into leaks. The fog droplets contain amorphous silica particles that clog air leaks less than ½” in size. Larger leaks are better sealed directly, and are often found by visual observation of the fog exiting the house exterior. The process is computer controlled to a desired level of sealing (typically, 0.5ACH at 50Pa). A continuous plot of decreasing air leakage, pumped sealant liquid volume, and compressed air pressure are displayed on a laptop computer.

Nate said that setup is the most time-consuming part of the process, with 2 to 3 hours required to seal duct vents and flue vents, and to lay plastic sheeting or paper on horizontal, upward facing surfaces (floors, tables, etc). Walls and ceilings do not attract the fog droplets and do not need to be covered. Window mullions and sills do not need to be covered. A light coating from the fog is wiped from these surfaces with a damp cloth after the sealing process is completed. The actual sealing process requires an hour or so, depending on the house volume and amount of leakage. A typical home will use less than 5 gallons of the AeroBarrier sealant (typically, 1 to 2 gallons are used).

The demonstration home started with an already low, as-built leakage of 1.1ACH at 50Pa. The home has closed cell spray foam insulation on exterior walls and roof. With a volume of approximately 62,000 cubic feet, the initial blower door air flow for maintaining 100Pa was 1500cfm. For smaller homes, the blower door fan would use smaller flow rings as would be done for a blower door leakage test.

Sean feels that AeroBarrier significantly reduces the time-consuming process of finding individual leaks, especially those that are fairly complex (eg, electrical or plumbing path leakages). The AeroBarrier sealant flows into electrical conduit boxes, sealing air gaps around wiring while leaving the junction boxes clean. Our Equinox House (SIPs, Structural Insulation Panel construction), by comparison, required 17 hours of labor and 70 tubes of caulk to reduce house leakage from 3ACH at 50Pa to 0.5ACH at 50Pa (see our ASHRAE Journal article for details).

Is AeroBarrier safe? The liquid carries an Underwriters Laboratories Greenguard rating. If you are curious what is made of, the Safety Datasheet lists the primary components. All personnel are cleared out from a home during sealing, however, the house can be entered to adjust the spray nozzles (with an appropriate respirator). The sealant fog is similar to theatrical fog composed of propylene glycol, one of the main components of the AeroBarrier sealant. Propylene glycol causes throat and eye irritation if protective precautions are not followed, but otherwise is considered low toxicity. The clogging agent, amorphous silicon dioxide (also called “fumed” silica) is a common thickening agent used in sealants, cosmetics, and food, as well as high performance insulation (VIPs, or Vacuum Panel Insulation).

Is AeroBarrier right for your project? Cost and availability in your area are primary factors. As AeroBarrier expands across North America, availability will increase. The cost needs to be compared to other sealing options, from barrier wraps and tapes, to manual search-n-plug. Zone 6 Energy is currently feeling its way to a cost model, which may be in the $1 to $2 per square foot house floor area. A simple SIPs construction, such as Equinox House, was straightforward to seal to high performance levels, however, more time was required to seal its exposed seams than would have been required by the AeroBarrier process. More complex house designs with hidden nooks and crannies, and retrofit projects are definite candidates for AeroBarrier consideration.

Figure 1: AeroBarrier demonstration home under construction near Lincoln Vermont

Figure 1: AeroBarrier demonstration home under construction near Lincoln Vermont Figure 2: Nate Gusakov of Zone6Energy (AeroBarrier installer) explaining the process. The cart contains a liquid metering pump and compressed air lines feeding 9 spray nozzle stands distributed on the home's three levels.

Figure 2: Nate Gusakov of Zone6Energy (AeroBarrier installer) explaining the process. The cart contains a liquid metering pump and compressed air lines feeding 9 spray nozzle stands distributed on the home's three levels. Figure 3: Nate mixes a 5 gallon bucket of the AeroBarrier sealant. The liquid is quite watery in comparison with latex paint, but has the same odor. Temperatures should be between 40F and 80F for application. A typical installation will use less than 5 gallons. The “fog” is similar to the amount of fog created when spray painting a house interior.

Figure 3: Nate mixes a 5 gallon bucket of the AeroBarrier sealant. The liquid is quite watery in comparison with latex paint, but has the same odor. Temperatures should be between 40F and 80F for application. A typical installation will use less than 5 gallons. The “fog” is similar to the amount of fog created when spray painting a house interior. Figure 4: Amorphous silica (also called "fumed" silica) is suspended in the solution and carried within fog droplets to leaks. Leaks larger than 1/2" in width are difficult to seal and waste sealant.

Figure 4: Amorphous silica (also called "fumed" silica) is suspended in the solution and carried within fog droplets to leaks. Leaks larger than 1/2" in width are difficult to seal and waste sealant. Figure 5: Nine spray nozzle stands (two nozzle heads per stand) were distributed throughout the home's three floors. Liquid sealant and compressed air (~60psig pressure) tubing are connected to each nozzle stand.

Figure 5: Nine spray nozzle stands (two nozzle heads per stand) were distributed throughout the home's three floors. Liquid sealant and compressed air (~60psig pressure) tubing are connected to each nozzle stand. Figure 6: Plastic sheeting is laid over horizontal surfaces. Window sills and mullions are left uncovered, but wiped with a damp cloth after the sealing operation. The fog does not coat vertical surfaces or ceilings.

Figure 6: Plastic sheeting is laid over horizontal surfaces. Window sills and mullions are left uncovered, but wiped with a damp cloth after the sealing operation. The fog does not coat vertical surfaces or ceilings. Figure 7: A sheet of cardboard is the only protection needed for the home's heat pump water heater.

Figure 7: A sheet of cardboard is the only protection needed for the home's heat pump water heater. Figure 8: All supply and return duct openings are sealed. Note the home's insulation is closed cell spray foam construction.

Figure 8: All supply and return duct openings are sealed. Note the home's insulation is closed cell spray foam construction. Figure 9: A blower door maintains 100Pa (0.4"H2O) house pressure, driving the fog sealant into leaks throughout the house.

Figure 9: A blower door maintains 100Pa (0.4"H2O) house pressure, driving the fog sealant into leaks throughout the house. Figure 10: A laptop computer monitors and controls the sealing process. The demonstration home started with a very respectable "as-is" leakage of 1.1ACH at 50Pa, with an end goal of 0.5ACH at 50Pa.

Figure 10: A laptop computer monitors and controls the sealing process. The demonstration home started with a very respectable "as-is" leakage of 1.1ACH at 50Pa, with an end goal of 0.5ACH at 50Pa. Figure 11: Nozzles spray droplets throughout the house. The droplets are small enough to stay suspended in air, traveling with air currents to leaks.

Figure 11: Nozzles spray droplets throughout the house. The droplets are small enough to stay suspended in air, traveling with air currents to leaks.