Key Points

- Smart Ventilation

Traditional HRV/ERV systems guess ventilation needs, while smart systems (like the CERV2) use real-time IAQ sensors to dynamically adjust airflow, improving both energy efficiency and air quality. - Comfort Advantage

Unlike passive HRV/ERV heat exchangers, CERV2’s heat pump actively conditions air - warming it in winter (avoiding cold drafts) and cooling/dehumidifying it in summer, resulting in greater comfort for occupants. - Performance Data

Sensible Recovery Efficiency and Total Recovery Efficiency calculations show much greater energy recovery efficiency than ERV or HRV systems. Compare 1.22 (SRE) and 1.91 (TRE) to the highest efficiency ERV and HRVs available (0.85-0.90).

CERV2 Smart Heat Pump IAQ Management

Build Equinox started with a blank sheet of paper in 2007 to develop an air quality management system for keeping indoor environments healthy. Healthy air quality cannot be detected by the human nose. The late Professor Ole Fanger demonstrated how poor air quality undetectable by human olfactory senses degrades human performance. Since then, evidence continues to build showing how imperceptibly poor air quality results in poor sleep, poor productivity, and airborne disease transmission.

Lawrence Berkeley National Laboratory’s 2013 report “Houses are Dumb without Smart Ventilation” appeared as we introduced the first generation CERV smart ventilator to the market. The LBNL report explains how smart ventilation systems such as the CERV improve both energy efficiency and air quality in relation to constant flow ventilation systems. Unless air quality is actively sensed, one is guessing that air quality is ok.

We’ve named our technologies “CERV” (pronounced “serve”), Conditioning Energy Recovery Ventilator, because our units deliver conditioned air to indoor spaces instead of pulling rooms away from comfort like typical ERV and HRV units. In this article, we discuss the similarities and differences between how ERVs, HRVs, and the CERV operate, as well as compare performance and comfort between the systems.

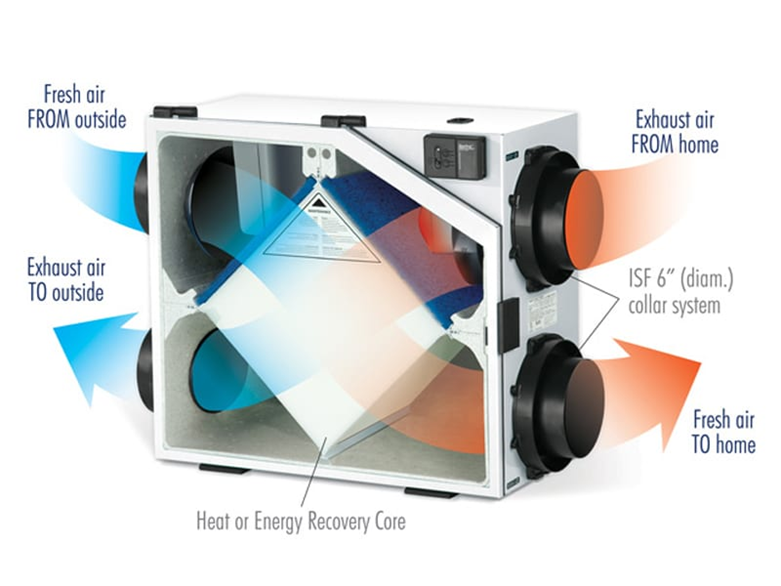

How ERVs and HRVs Work

Figure 1 shows a schematic of an ERV and HRV consisting of a heat exchanger core with fresh air supply and exhaust air streams exchanging energy as they pass through the core. For ERVs, the heat exchange core is made of a water vapor permeable material allowing water to transfer from higher to lower vapor pressure regions. Water vapor transfer between incoming fresh air and outgoing exhaust air can be beneficial for some conditions, and detrimental in others. For example, warm humid outside air can transfer moisture to exhaust air when the exhaust air has lower humidity. House exhaust air passing through a bathroom with wet shower walls and wet towels may recycle exhaust air humidity to incoming fresh air adding more moisture to a house!

How Heat Pump Energy Recovery Works

Figures 2 and 3 are heat pump schematics of CERV2 in winter heating (Fig 2) and summer cooling (Fig 3) operation. During winter, the CERV2 heat pump “pumps” heat from exhausted room air to incoming fresh air. When fresh air is not required, the CERV2 operates in recirculation mode that is important for filtering indoor particulates and for distributing fresh air “stored” in unoccupied rooms. Depending on CERV2 temperature setpoints, the CERV2 can contribute its comfort conditioning capacity to a home during recirculation. This is an important feature for maintaining comfort in unoccupied rooms.

CERV2 heat pump energy recovery provides important latent (moisture) management to a home. Unlike an ERV with moisture permeable exchanger core, CERV2’s separated heat pump heat exchangers do not transport moisture from one air stream to the other. During summer, incoming warm, humid air is dehumidified by the CERV2’s cooling coils. Indoor moisture freezes on the CERV2’s cooling coils during winter operation, with the heat pump converting water vapor condensation phase change energy into sensible heating.

Heat Pump Energy Recovery and Comfort

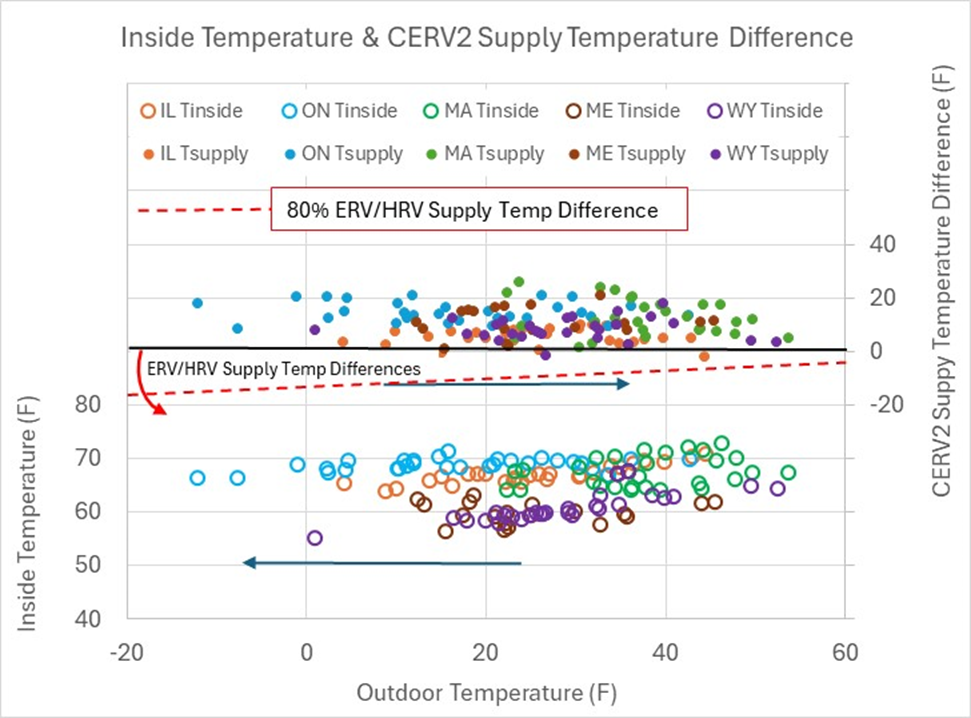

Figure 4 below shows air temperature data from 5 CERV units located in Ontario, Maine, Wyoming, Massachusetts, and Illinois. The data are daily averages of 1-minute readings for January 2025 and includes all CERV2 operations such as recirculation, ventilation, and coil defrost periods. The graph’s lower portion shows indoor temperatures for the five homes. Home indoor temperatures vary by 10F due to homeowner preference differences.

The top section of Figure 4 shows temperature differences between CERV2 supply air temperature and house indoor temperature. CERV2 supply temperatures vary due to differences in user selected temperature setpoints, CERV2 fan speeds, pollutant setpoints (CO2 and VOCs), pollutant generation rates, house infiltration, scheduled ventilation periods, and triggered ventilation events (eg, bathroom usage or cooking).

During winter, CERV2 delivery temperatures are warmer than room temperature unlike HRVs and ERVs that supply air below room temperature. A red dashed line drawn on Figure 4 shows supply air temperature difference for an 80% efficient ERV or HRV. A home with 68F indoor temperature and 20F outdoor temperature will be supplied with 59F air from an 80% efficient ERV and HRV.

A common ERV/HRV problem occurs in rooms with fresh air supply ducts with no comfort conditioning. A ductless minisplit located in another region of the residence may have plenty of capacity, but ERV/HRV supply air flowing out of the room prevents conditioned air from flowing into the room. A bedroom occupied 8 hours a day has 16 hours for unconditioned air to pull the room away from comfort. Summer is similar, but worse because an unoccupied room pulled to warmer than comfort conditions by ERV/HRV supply air is further removed from comfort during occupancy from human heat output.

Efficiency of Heat Pump Energy Recovery

CERV2 units are dynamic machines designed to follow ever-changing air quality and comfort conditions. Static laboratory tests do not properly characterize CERV2 efficiency and operation. A proper test, based on air quality management, would release pollutants into a space to determine how quickly and energy efficiently a ventilation system responds to poor air quality.

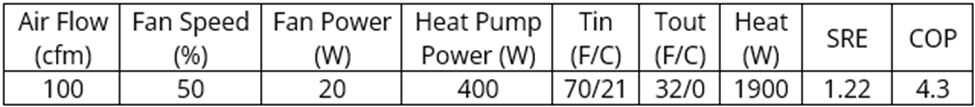

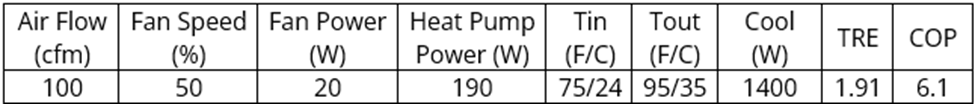

Tables 1 and 2 use CERV2 performance information to calculate HVI (Home Ventilating Institute) SRE (for heating) and TRE (for cooling) parameters. Operating the CERV2 at a constant air flow at 100cfm results in high SRE and TRE values. COP values for heating and cooling energy recovery modes are also listed in Tables 1 and 2. COP is a more proper way to compare performance, reflecting energy exchange relative to utility energy needed to operate the heat pump.

In the beginning of this article, we mentioned LBNL’s report on smart ventilation achieving higher energy efficiency and maintaining better air quality than constant flow ERV and HRV units. Heat pump energy exchange is efficient, but the real gains in energy efficiency and air quality are from knowing when and how much ventilation is needed.

For example, a 2500sqft home with 4 bedrooms requires 112.5cfm ventilation according to ASHRAE 62.2 ventilation standard. Build Equinox healthy air standards recommends fresh air based on human pollutant generation rates which translates to 40cfm per person, or 80 to 120cfm for during occupancy by 2 to 3 people. On average, we spend 2/3s of time in our homes, which smart ventilation automatically senses, effectively reducing ventilation by 1/3. This is a significant energy savings gained while maintaining excellent air quality. Ideally, as every indoor space is “smart ventilated”, every time you walk through a doorway, 40cfm of fresh, filtered unpolluted air should be pouring into that space with you…and turned off when you leave.

Build Equinox focused on human health and well-being, and developing technologies to improve quality of life in a sustainable manner. We appreciate your following our journey!