Does Your Ventilation System Make the Grade?

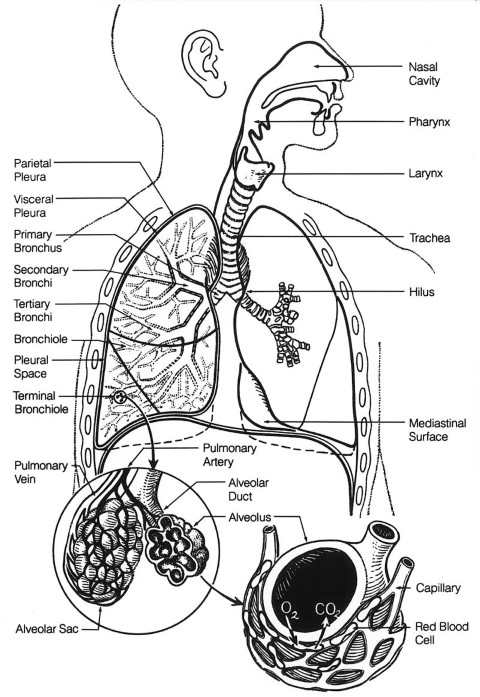

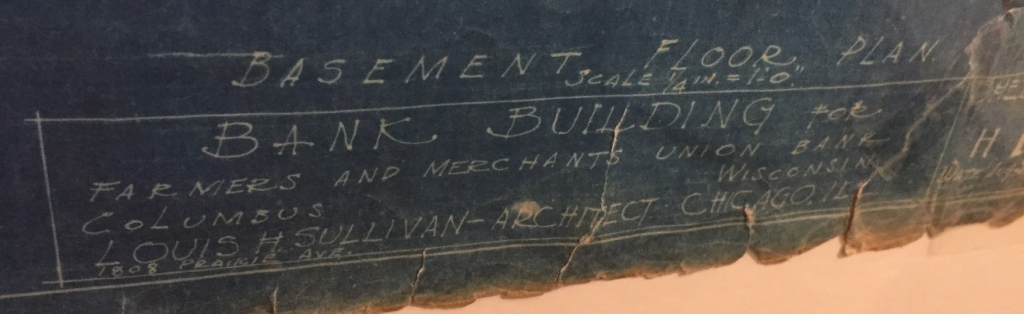

The human respiration system is an exquisite ventilation system that efficiently moves air through the nasal cavity, larynx, pharynx, trachea, bronchial tubes and into the lungs. We go into distress when any part of the respiratory system is not functioning properly. Our health is similarly stressed when any section of our home’s ventilation system is improperly designed or poorly installed.

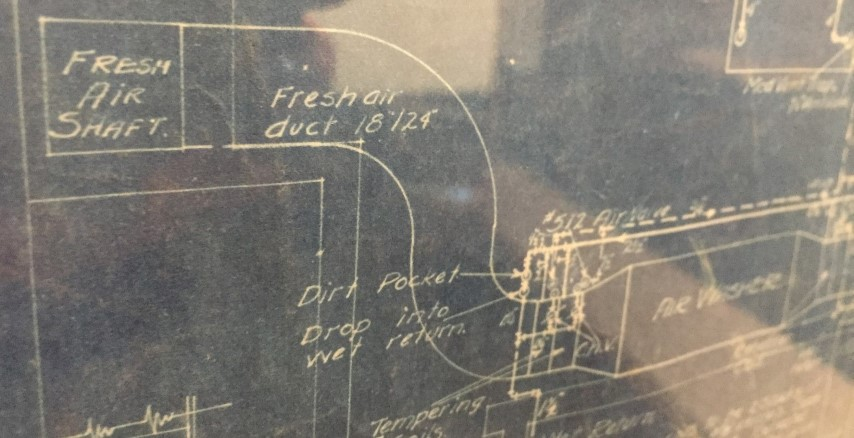

Part 2 of Ductology focuses on the performance of ventilation ductwork. We describe two “rough-in” tests that should be performed on installed duct systems before ducts are hidden behind wallboard and ceilings. The cost and heartache associated with inadequate ducting after finishing touches have been applied to a home are immense. And the cost of living with a poor ventilation system is even greater in terms of impact on home occupant health and lifetime operational cost for excessive blower power.

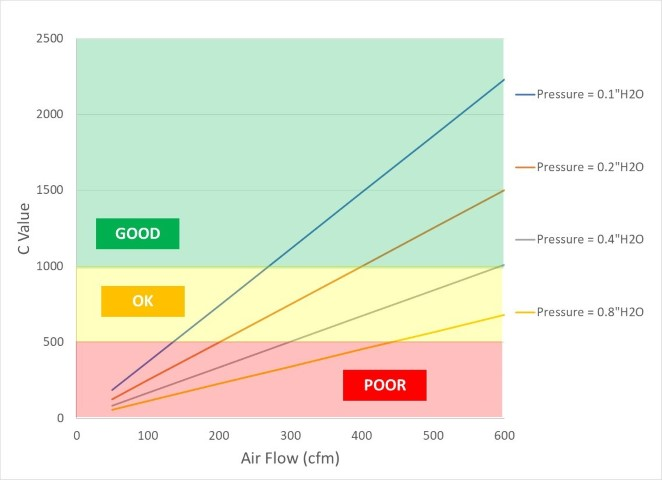

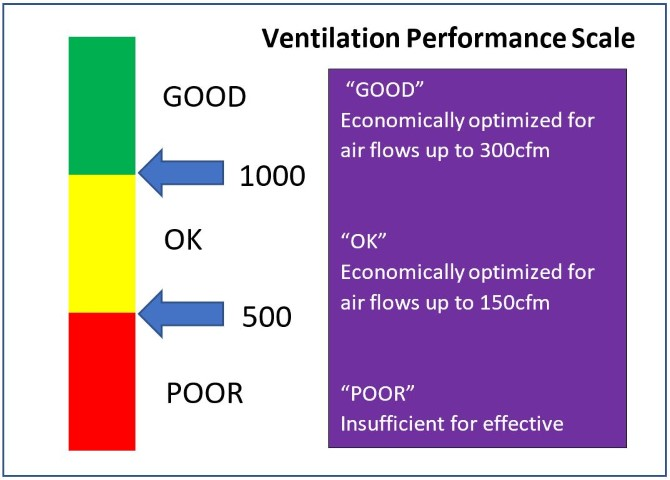

The ventilation system test we present is straightforward to implement and interpret. Ventilation ductwork that scores above 1000 are good. Duct systems scoring below 500 are not so great.

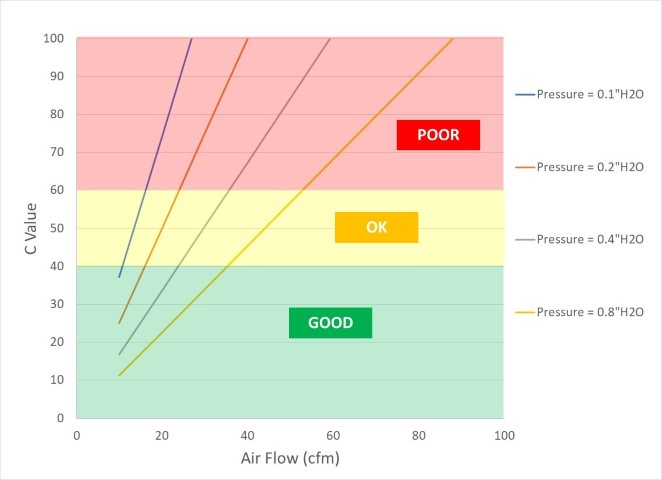

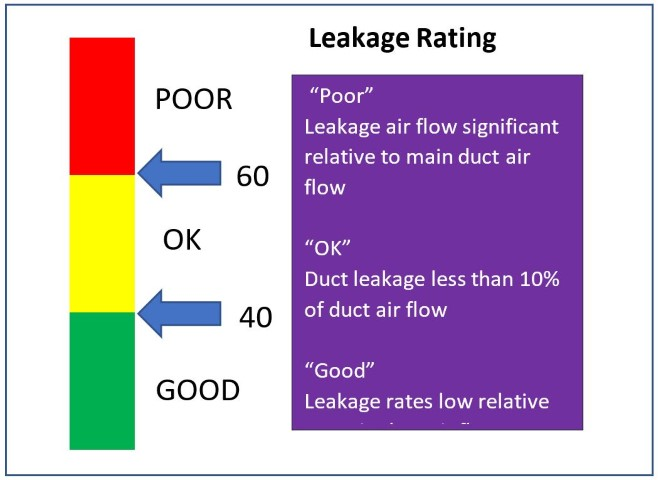

A second test assesses duct system leakage. The duct leakage test uses the same duct leakage test procedure currently used in homes. We re-interpret test results differently, however, by relating duct leakage to the duct air flow performance test. Duct leakage should be less than 5% of the design air flow, consistent with ASHRAE’s view of duct leakage. Using the same scale used for duct performance, a duct leakage score of 50 or less is desired for a duct network with a performance score of 1000.

Our detailed report, Ductology – Part 2, includes analytical and experimental validation of the duct system performance and duct system leakage tests. Example duct system performances are included. Also included in the report is a section that develops a model for relating house infiltration to blower door performance. The infiltration model uses the same analyses used to characterize duct performance and duct leakage. In this manner, one can understand the interrelation of building infiltration, duct performance and duct leakage.

Blower door testing of homes is now commonplace and is often required by local building code authorities. The duct testing procedures we describe are ones that should similarly be conducted on every home. Select Test 1 (Duct Performance) and Test 2 (Duct leakage) for PDF copies of the test procedures. Appendix C in the Ductology – Part 2 report shows a test setup for determining duct performance.

Stay tuned for future articles and reports that explore these effects, and how the CERV smart ventilation system is designed to manage air quality in all homes, regardless of whether they are today’s high performance houses or homes built years ago.

Test 1: Duct System Performance

Build Equinox recommends performing the following “rough-in” duct test on supply and return ventilation ducts prior to installing air handlers or fresh air ventilation units.

The performance test consists of the following steps:

Test 2: Duct Leakage

Build Equinox recommends the following rough-in duct leakage performance test for supply and return ventilation ducts. The leakage test procedure is the same as the performance test except that all duct outlets/inlets are sealed.

The leakage test consists of the following steps: